The objective of the dynaTWIN project is to provide the manufacturing market, particularly the metallurgical industry, with an innovative technology that helps to better understand the effects of vibrations in the milling of complex parts, detect possible machine failures, and make the right decisions to reduce vibrations, thus offering high-quality, defect-free products and reducing costs in the production plant.

In addition, the significant reduction of waste generated by manufacturing processes due to improved milling will contribute to enhancing the environment and aligning with the goals of the European Green Deal.

AICRUM is developing the Digital Twin Module, a Virtual Reality application that acts as a dynamic twin (Dynamics Twin) of the milling machine, to visualize the vibrations of the milling machine and allow easy and straightforward interaction with the machinery in the production plant, leading to the self-optimization of the production system. It aims to identify or anticipate possible machine breakdowns and take corrective actions or preventive measures to limit and reduce vibrations.

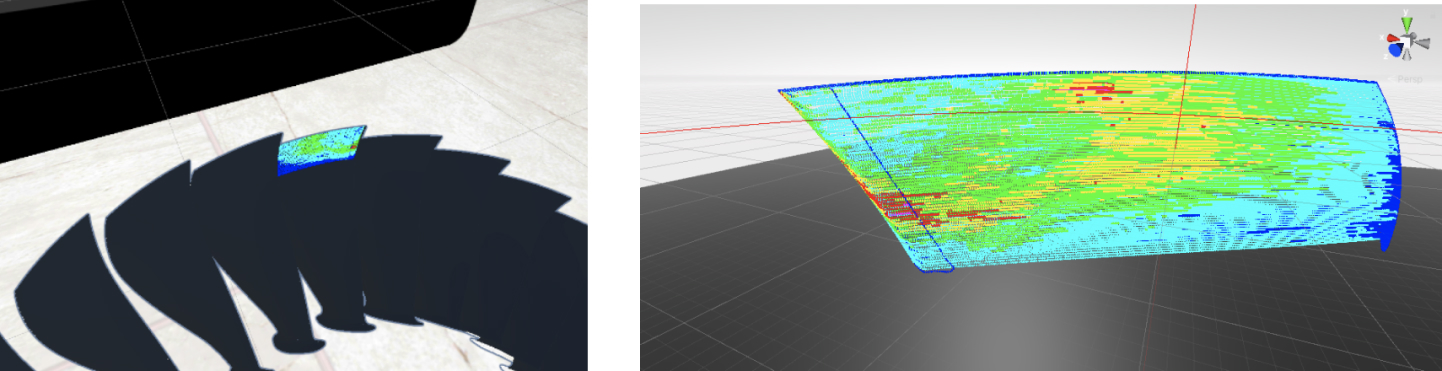

The vibration data is processed, visualized, and analyzed with respect to the 3D representation of the part in the virtual environment. The geometric information makes the process more transparent and allows easy visualization of where large vibration amplitudes occurred, where the spindle moved abruptly due to rapid acceleration changes, where the spindle speed decreased, etc.

VR enviroment of the milling machine Simulation data loading

VR enviroment of the milling machine Simulation data loading

With a graphical representation based on a color scale, the machine operator can see the machine’s condition in detail and make preventive and maintenance decisions accordingly.

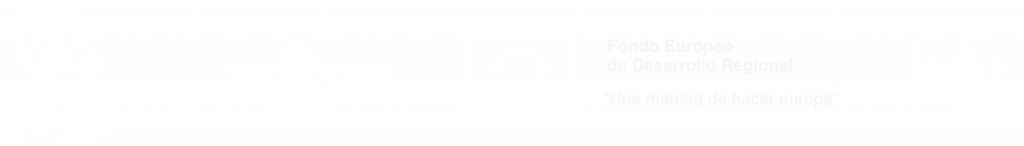

Representation of force points resulting from milling

Representation of force points resulting from milling

The Digital Twin Module provides a software solution consistent with the data to enhance the stability of milling processes, even the most complex ones.

Representation of a workpiece (resulting from the simulation) with milling result data in different colors

Representation of a workpiece (resulting from the simulation) with milling result data in different colors

The consortium is made up of 2 SMEs (ModuleWorks, Germany, and AICRUM IT, Spain), a Technology Center (Fraunhofer IPT, Germany), and a large company in the aerospace sector (TEI, Turkey).

For AICRUM IT, participation in the EUROSTARS dynaTWIN project represents a unique opportunity to develop a product that can open a new market niche in the manufacturing industry, with a primary focus on the aerospace industry.

This project has received funding from the joint Eurostars-2 program with co-financing from CDTI and the Horizon 2020 Research and Innovation Framework Programme of the European Union.